Rethinking pallet patterns for automation

When you’re stacking pallets by hand or with a basic system, the pattern is chosen based on the product. It’s shaped by box size, packaging stability, and how much a person can lift. In most cases, the pattern stays the same unless the product changes.

With automation, that same pattern might still work—but the possibilities open up.

A robot can stack higher than a person. It can handle heavier boxes, at a faster rate. It can pick up two or three units at once, boosting throughput and unlocking better ROI from each pallet built.

And when the system includes software to optimize the stacking pattern based on your box dimensions and load goals, it takes the guesswork out of choosing the most efficient layout.

In this article, we’ll explore the most common pallet stacking patterns, how they perform in automated environments, and what to consider when aligning your packaging, system capabilities, and production targets.

Top pallet stacking patterns

Below are four commonly used pallet stacking patterns. Each offers trade-offs in stability, speed, and how easily it integrates into automated palletizing systems.

Brick / interlocked pattern

This pattern offsets each layer by alternating the direction or position of boxes, similar to a brick wall. It improves load stability by distributing weight and resisting shifting, making it ideal for transport or uneven product loads.

Things to consider for automation: Interlocked patterns often require rotating boxes between picks. If your system lacks orientation control or servo tooling, this adds complexity and can slow down cycle time. With proper box turning mechanisms, this pattern is well within reach of automated systems.

- Stability: High

- Automation-readiness: Moderate to high (depending on box orientation capability and gripper design)

- Ideal for: Boxes or rigid containers

- Throughput speed: Medium

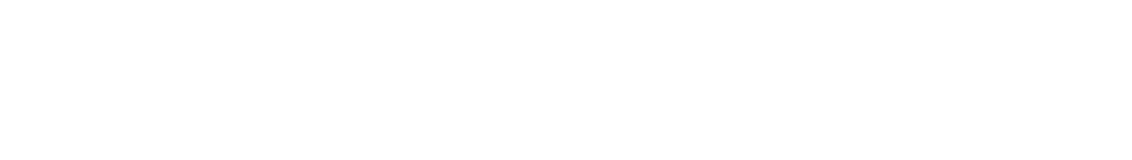

Pinwheel pattern

The pinwheel pattern arranges units at 90-degree angles in a repeating sequence within the same layer. It’s commonly used for soft, flexible, or deformable items like bags because it minimizes slippage and forms a compact, self-supporting load.

Things to consider for automation: This is one of the more complex patterns to automate due to varying angles, irregular packaging shapes, and lower pick consistency. Systems need robust tooling and motion logic to manage orientation and placement repeatably.

- Stability: High

- Automation-readiness: Low to moderate

- Ideal for: Bags, soft goods, irregular packaging

- Throughput speed: Slower unless tightly controlled

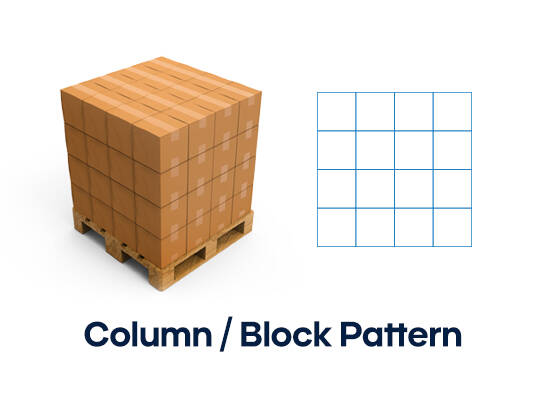

Column / block pattern

In this pattern, boxes are stacked directly on top of each other in straight, vertical columns. It’s the most space-efficient and fastest to build, especially when the packaging is rigid and uniform. However, it may sacrifice stability if the load isn’t tightly wrapped or if box strength is low.

Things to consider for automation: Column stacking is highly automation-friendly. It requires no rotation, supports multi-pick grippers, and offers predictable motion paths, making it ideal for maximizing throughput on most robotic palletizers.

- Stability: Moderate

- Automation-readiness: High

- Ideal for: Uniform boxes or trays

- Throughput speed: High (especially in multi-pick operations)

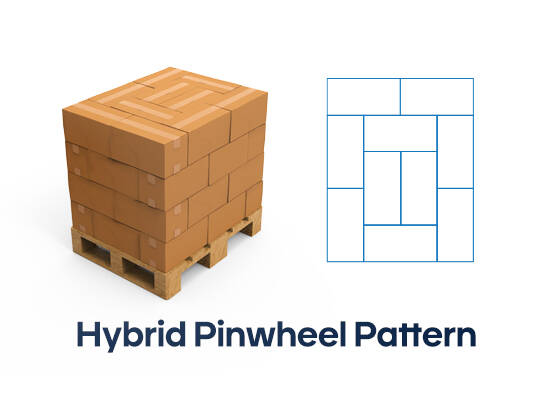

Hybrid patterns

Hybrid patterns combine features from column and interlocked arrangements. For example, alternating brick and column layers can improve overall load integrity while maintaining a high stacking speed. These are often used to balance stability and cycle time in production environments.

Things to consider for automation: The complexity of automating hybrid patterns depends on how much variation exists between layers. If layer transitions require changes in box orientation, the system must support rotation or flexible pick logic. With proper setup, hybrid patterns can be optimized for both stability and speed.

- Stability: High

- Automation-readiness: Moderate to High (depends on layer complexity and gripper/orientation capabilities)

- Ideal for: Mixed product types, high-speed environments

- Throughput speed: Optimized (based on layer design and cadence)

Each of these patterns can be optimized further with the right software and system configuration. The key is matching the pattern to the product and your process.

Try out our configurator to see how easy it is to switch from one pattern to the next!

What impacts your pattern choice in an automated line

Not all pallet stacking patterns behave the same when automation is involved. Even if a pattern works well with manual labor, adding a robot introduces physical and system-level constraints that can affect throughput, consistency, and load stability.

This section outlines the objective factors that influence how well a pattern performs in an automated palletizing setup.

- Box shape, rigidity, and consistency: Automation depends on repeatable placement. If your boxes are soft, uneven, or prone to deformation, you’ll need a more stable pattern and possibly tighter wrapping to maintain stack integrity.

- Even or odd box counts per layer: Some stacking patterns rely on even box counts to stay balanced. When running odd counts, the system must adjust placement logic or accept a slightly less optimized layout.

- Pallet size and layout constraints: Euro pallets, standard GMA pallets, or custom sizes require different pattern logic. Your chosen pattern should maximize pallet surface area without causing overhang or leaving gaps that reduce load stability or transport efficiency.

- Robot reach and motion range: Your stacking pattern must fit within the robot’s working envelope. Taller stacks or wide pallets may require track-mounted robots, coordinated axes, or changes to the cell layout. If reach is limited, column stacks near the base are easier to execute than patterns that require deep, angled placement.

- Single-pick vs. multi-pick capability: If your system supports multi-pick, column patterns will likely offer the highest throughput. More complex patterns that require rotated or offset placements often need single picks to maintain accuracy. The right gripper setup is key to enabling either approach.

- Vision, orientation, and placement control: For patterns with rotated or alternating box positions (like brick or pinwheel), your system may need box orientation tooling, conveyor-based alignment, or vision systems to guide placement. These add precision but also increase complexity.

- Wrap method and load support: The pattern you use must work with your stretch wrap settings and pallet constraints. Column stacks depend heavily on wrap tension and box integrity. Interlocked patterns provide more inherent stability but may not suit all packaging types.

- Product handling or ventilation needs: In food or pharma environments, patterns may need intentional gaps to allow airflow or prevent product damage. These custom layouts must be supported by your system’s recipe logic and load validation tools.

- Software-generated vs. manual stacking recipes: Some systems, like TOMA™, can auto-generate optimal pallet patterns based on box dimensions, layer count, and stability goals. This speeds up setup and ensures consistent results. Manual recipes can still be used when needed, but often take more time to maintain and validate.

Guide to choosing the right stacking pattern with automation

When you’re selecting, or validating, a stacking pattern for automation, the right choice depends on your product, your goals, and how your team will interact with the system.

This section offers a decision-making framework to help you choose the best-fit stacking approach based on your operation’s needs and packaging constraints.

| Category | If… | Then consider… |

|---|---|---|

| Product & packaging type | You’re stacking rigid boxes or trays | Column or hybrid patterns for faster, simpler automation |

| You’re stacking bags or soft packaging | Interlocked or pinwheel patterns to improve load containment | |

| Your packaging is consistent | Fixed stacking recipes for fast setup and repeatability | |

| Your packaging is variable | Systems with auto-generated recipes that adjust per SKU | |

| Production requirements | You run a high-speed line | Column stacks with multi-pick logic to maximize throughput |

| You run a moderate-speed or stability-focused line | Hybrid or interlocked patterns to prioritize load security | |

| You build full pallets | Standardized, symmetrical patterns that repeat cleanly | |

| You build partial pallets | Custom stacking logic to maintain balance and prevent shifting | |

| Handling & shipping environment | Your pallets are shipped long distances or handled often | Interlocked or hybrid patterns to avoid load shifting |

| Your pallets stay in controlled environments | Column patterns to boost speed and efficiency | |

| System & operator capabilities | Your team is engineering-driven | Manual recipe adjustments may work fine |

| Your team relies on operators at the line | Preloaded or auto-generated stacking patterns for ease of use | |

| Your system includes recipe optimization software | Enter box specs to generate the most efficient pattern | |

| Your system does not include optimization tools | Stick with proven patterns that match your packaging and goals |

This table helps align your stacking pattern with your operational needs, not just what’s technically possible.

Choosing a pattern that fits your product, speed, and system capabilities ensures your palletizer runs smoothly and delivers consistent performance.

Common mistakes in pallet stacking patterns

Even with automation in place, choosing the wrong stacking approach can slow down production, reduce load stability, and lead to unnecessary downtime. Avoiding these common mistakes can help you get more value out of your palletizing system.

Thinking like a human, not a system

Manual palletizing habits don’t always translate well to automated environments. A layout that looks good visually may not be optimized for robot motion, repeatability, or consistent load quality.

Ignoring the speed and efficiency tradeoff between patterns

Interlocked patterns may offer more stability, but they often take longer to build. Column stacks are faster and simpler for robots but require tighter wrapping or uniform packaging. Picking the wrong one for your cadence can bottleneck the line.

Manually creating patterns instead of using smart recipe logic

Relying on hand-drawn layouts or trial and error wastes time. Modern systems like TOMA include algorithms that can suggest optimized patterns based on the size, weight, and stability of your product. These tools remove the guesswork and help you get better performance from your existing packaging setup.

Not accounting for packaging variations

Rigid boxes behave differently than soft bags or deformable items. A pattern that works for one product may fail for another if packaging characteristics aren’t considered in the stacking logic.

Understanding these missteps ahead of time helps prevent rework, downtime, and costly product damage, especially in high-throughput operations.

Looking to automate your palletizing?

If you are trying to improve pallet quality, reduce manual work, or speed up production, choosing the right palletizing system is key. You need a solution that’s easy to use, and fits your products and workflow.

TOMA™ makes automation simple.

The TOMA™ PAL-0830 is a standardized palletizing system designed for manufacturers who want reliable results without needing robotics experience.

At the center of TOMA™ is a touchscreen powered by MOVN™.

Whether you provide a preferred stacking pattern or start from your box dimensions, TOMA’s system uses built-in logic to generate a palletizing recipe that fits your goals. And when manual input is needed, operators can still select or modify patterns without code.

- MOVN™ adjusts the stacking logic based on your goals, whether that’s more speed, better stability, or tighter stacks. It even supports multi-pick setups like placing two or three boxes at once, while keeping the pattern consistent.

- The TOMA™ palletizer runs on a FANUC CRX-30iA cobot that handles up to 66 lb and can reach up to 8 picks per minute. It also works with dual conveyors, so you can stack from multiple lines at the same time.

- With Necton™ technology, you can track performance and make real-time changes when needed.

If you are ready to simplify your palletizing and take control of your stacking recipes, speak with a TOMA™ expert to see how easy it can be to automate with confidence.

Frequently asked questions

Interlocked or brick patterns are generally considered the most stable. They offset each layer to prevent shifting, which is especially useful for transport over long distances or for loads with varied weight distribution.

Column patterns are typically the most automation-friendly. They allow for faster stacking and simpler motion paths. However, hybrid patterns that blend speed and stability are often used in systems that support more advanced stacking logic.

Start by evaluating your product type, packaging consistency, pallet size, and throughput requirements. Then, choose a pattern that fits those needs while maintaining load stability. Automation software can help generate the right stacking recipe based on these factors.

Yes, but they require more precise control and coordination. Interlock and pinwheel patterns can be automated successfully with the right gripper, motion strategy, and pattern logic, especially if your system supports multi-pick and advanced placement.

They use pre-programmed stacking recipes, consistent pick-and-place accuracy, and proper load validation. Tools like MOVN™ also check for pallet footprint and height compliance to reduce the risk of unstable loads before the first box is placed.

Interlocked stacking staggers boxes across each layer to improve load stability. Column stacking aligns each box directly above the one below, which speeds up automation but may require tighter wrapping or more consistent box sizes to stay stable.

Transform your palletizing process

Discover how automation can revolutionize your packaging line. Optimize speed, stability, and efficiency with tailored pallet stacking solutions.