What’s the real ROI of a cobot palletizer?

Manual palletizing drains your budget, your team members, and your productivity. Automation seems like the obvious solution. But how can you confidently determine if a cobot palletizer will pay off—and when?

This article introduces seven main steps taken from the framework of our ROI Calculator for Cobot Palletizing. We’ve built the calculator for real-world conditions, not just idealized spreadsheets. Unlike generic ROI tools, our ROI Calculator for Cobot Palletizing takes into account variables that other calculators often overlook.

If you’re looking for a clear answer to the question, “How long will this take to pay off in my plant?”, you’re in the right place.

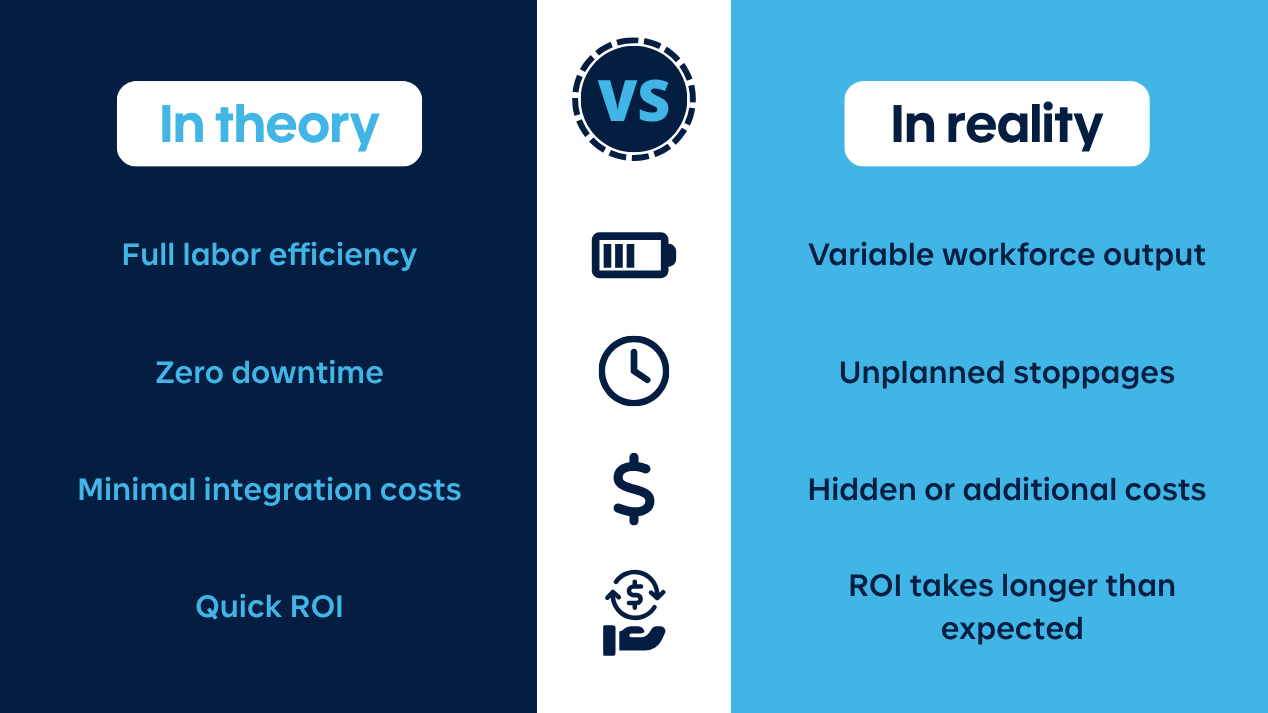

Why basic ROI formulas fall short

Most ROI calculators oversimplify the math. They assume perfect conditions:

- Full labor efficiency

- Zero downtime

- Minimal integration costs

But those aren’t the conditions most plants operate under. A rushed or incomplete ROI projection can lead to two common mistakes:

- Investing in a system that takes longer than expected to pay off

- Walking away from a project that could have delivered strong returns

To make a confident decision, you need a framework that reflects how automation performs in real-world conditions—with real team members, real processes, and real production demands.

The value most people miss

ROI reflects the operational stability and strategic flexibility you gain once automation is in place.

Reducing dependency on hard-to-staff roles lowers labor costs, decreases production delays from last-minute callouts, reduces training churn, and allows your team members to focus on higher-value tasks.

Reliable palletizing also improves your ability to plan and scale.

With consistent output and predictable performance, it’s easier to meet delivery deadlines, win new business, and expand without overextending your team.

These benefits are harder to quantify, but they often drive the most meaningful impact—keeping lines running, customers satisfied, and your team focused on growth.

The 7-step framework for calculating real-world ROI

Built around the true costs, savings, and performance factors manufacturers face every day, these steps will help you make informed decisions with confidence.

Here’s how it works:

Step 1: Calculate total system costs

Start with your quoted equipment price. Add any one-time costs related to integration, installation, training, conveyor modifications, layout changes, or risk assessments. This gives you the total investment required to get up and running.

Step 2: Estimate ongoing annual costs

Once the system is live, you’ll have recurring costs such as electricity, preventive maintenance, and occasional service or repairs. Even rare breakdowns can result in lost shifts, so it’s wise to budget for unplanned downtime upfront.

Step 3: Identify the labor costs that will be reduced or reallocated to higher-value tasks

Tally all labor-related expenses you aim to eliminate or reduce. This includes not only wages, but also bonuses, benefits, shift gaps, injury-related absences, and the costs of recruiting and retraining due to turnover.

Step 4: Adjust for labor and cobot efficiency

Manual labor is rarely 100% productive, especially in repetitive roles. If a team member performs at 85% efficiency, that directly impacts your real cost per unit. Similarly, most palletizing systems won’t operate at full speed 24/7. Be sure to factor in a realistic efficiency rate based on your specific application.

Step 5: Add expected productivity gains

Unlike team members, robotic palletizers don’t need breaks, and they won’t slow down during longer shifts. In many facilities, a palletizing system enables an extra shift or increases output without adding headcount. That throughput gain can significantly accelerate your ROI.

Step 6: Include reductions in product damage and injury

Inconsistent stacking leads to damaged goods during transit, and manual palletizing often results in repetitive strain injuries for team members. Robotic systems help reduce both, lowering rework, waste, compensation claims, and insurance premiums.

Step 7: Calculate your adjusted payback period

Use the full system cost, adjusted labor savings, throughput improvements, and reduced risk costs to calculate how long it will take to break even. The result is an ROI that reflects how your plant actually operates—not just how a spreadsheet thinks it should.

Curious about your numbers?

We’ve built our own Friendustrial™ ROI Calculator to help you apply each of these steps to your own operation. It’s the most complete tool available for estimating palletizer ROI with real-world variables, not just rough guesses.

Why the TOMA™ Palletizer is designed for quick ROI

The TOMA™ PAL-0830 is a fully integrated solution built to deliver a fast, measurable return.

With a 66 lb (30 kg) payload and speeds of up to eight cycles per minute, the PAL-0830 handles demanding palletizing tasks while maintaining a compact footprint that fits into tight production zones.

At the heart of the system is MOVN™, TOMA™’s proprietary HMI software. It’s designed for everyday team members—not robotics experts. There’s no need to write code or manually teach positions. Just enter your product specs, choose a pallet pattern, and press start.

Because it’s intuitive and designed for quick deployment, you avoid lengthy installation delays and reduce startup costs. This allows you to reach your ROI targets faster—seeing operational improvements within days or weeks, even though full payback is typically achieved over a longer timeline. Whether you operate on a single shift or across multiple shifts, TOMA™ offers small and medium-sized businesses an intuitive, scalable, and cost-effective path to automation.

Learn more about the TOMA™ Palletizer and how it can optimize your end-of-line operations.

Frequently asked questions

To calculate ROI, subtract your total system and operating costs from the labor and efficiency savings you expect to gain. Then divide by the total investment cost. Our ROI Calculator for Cobot Palletizing walks you through this in detailed steps, including real-world variables like labor efficiency, downtime, and injury-related costs.

Payback periods vary based on shifts, labor costs, and system efficiency. For a system like the TOMA™ Palletizer, many manufacturers estimate ROI in as little as 9 to 18 months, especially when replacing manual labor across multiple shifts.

You should include fixed costs (equipment, software, installation), variable costs (training, integration, layout changes), ongoing operating costs (maintenance, electricity), and manual labor costs being replaced. Don’t forget to factor in potential savings from injury reduction, damage prevention, and increased throughput.

While even a single-shift operation can benefit, most companies see faster ROI when the palletizer runs at least two shifts of eight hours per day. The more hours your system runs, the quicker it pays for itself.

Cobot palletizers offer consistent output, lower injury risk, and no turnover or sick days. While the upfront cost is higher than labor, the ongoing savings and performance gains typically lead to lower costs and higher efficiency over time, especially in repetitive or labor-intensive tasks.

Let’s get MOVN™ toward your ROI

You’ve seen what a realistic ROI calculation looks like and why it matters. Now it’s time to apply it to your own operation.

Use our TOMA™ online configurator to estimate your cycle time, layout fit, and project scope in minutes. It’s a quick way to see if the PAL-0830 is the right fit for your end-of-line needs.

Want a second look at your numbers? Our team is here to help—connect with a Premier Tech expert to review your application and build a data-driven case for your investment.