Palletizing technology: top trends to watch in 2026

Explore the top palletizing technology trends for 2026, including next-generation plug-and-play automation, accelerated operator upskilling, and evolving safety standards shaping the industry.

As automation continues to reshape food, logistics, and manufacturing industries, expectations for palletizing systems are set to evolve further in 2026. Today’s manufacturers increasingly prioritize user-friendly solutions, rapid deployment, and seamless integration across the entire production environment.

Labor shortages and the growing complexity of products are driving teams to seek palletizing technologies that are intuitive, adaptable, and fully compliant with the latest regulations from day one.

Drawing on recent projects and close conversations with industry partners, our team at Premier Tech has identified the key trends that will define palletizing automation in 2026—along with practical insights to help manufacturers prepare for their next move.

1. Application-specific interfaces replace traditional robot programming in 2026

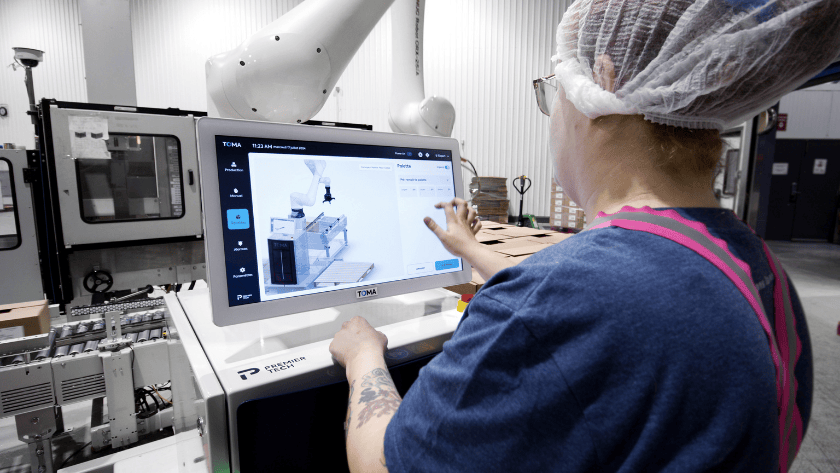

Palletizing systems are becoming significantly more accessible as manufacturers move beyond traditional robot programming environments. In 2026, the trend is clear: intuitive, task-specific interfaces are replacing complex coding and specialized engineering requirements.

Today’s newest palletizing solutions feature operator-focused interfaces, allowing team members to:

-

Configure pallet patterns

-

Adjust operational settings

-

Create or update recipes

-

Manage the system—without writing code or needing an automation engineer on-site

This industry shift reflects a growing expectation: palletizing systems should be fully operable by the production team, not just by technical specialists. Visual builders, guided setup screens, and intuitive controls make it possible for line operators to confidently manage production changes and troubleshoot issues on the fly.

User-centric design delivers real benefits:

-

Shorter training periods for new team members

-

Faster and easier changeovers

-

Reduced downtime during shift changes or role transitions

Ultimately, the move to more user-friendly interfaces empowers teams to act quickly and independently, driving greater productivity, smoother workflow, and a faster return on investment.

Premier Tech’s MOVN™ interface supports this by giving operators a visual, no-code environment to set up, adjust, and run palletizing jobs with minimal training.

2. Performance versus expectations: demand for transparency in 2026

As automation demand grows, skepticism is also rising around the claim of "plug-and-play" solutions. In 2026, pallet systems marketed as turnkey must do more than just promise—manufacturers now seek proof of fast, low-friction deployment.

Today’s buyers are better informed and more selective. Before deciding, they expect systems that:

-

Arrive preconfigured for their specific products

-

Install quickly, without major production rework or unexpected delays

-

Allow for cycle time and layout validation—sometimes through digital twins or simulations—before the purchase

This marks a big shift toward deployment readiness. Teams, especially those with limited in-house engineering resources, need equipment that fits seamlessly into their operations with minimal customization or interruption.

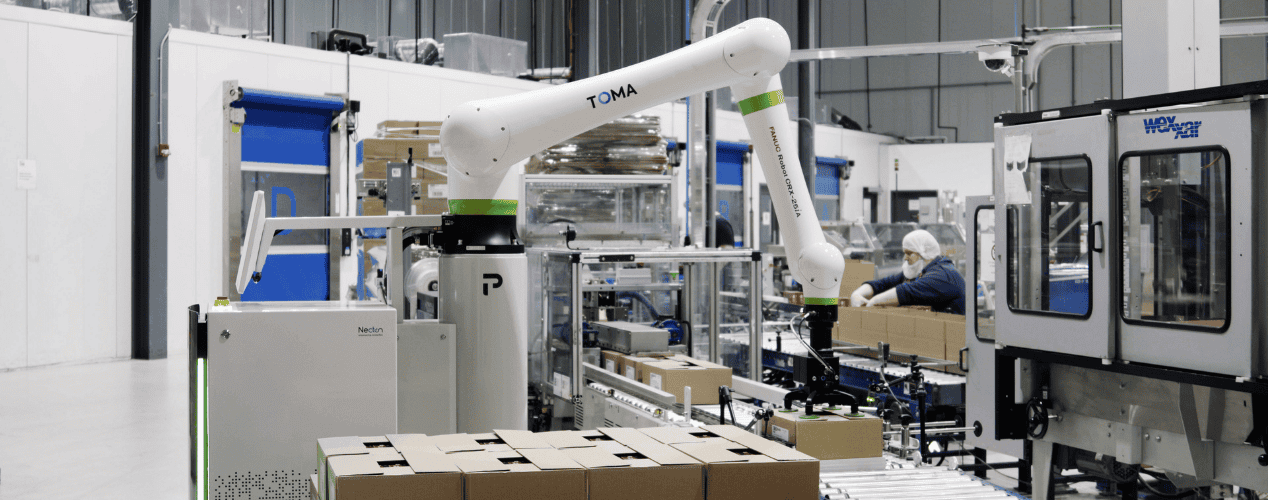

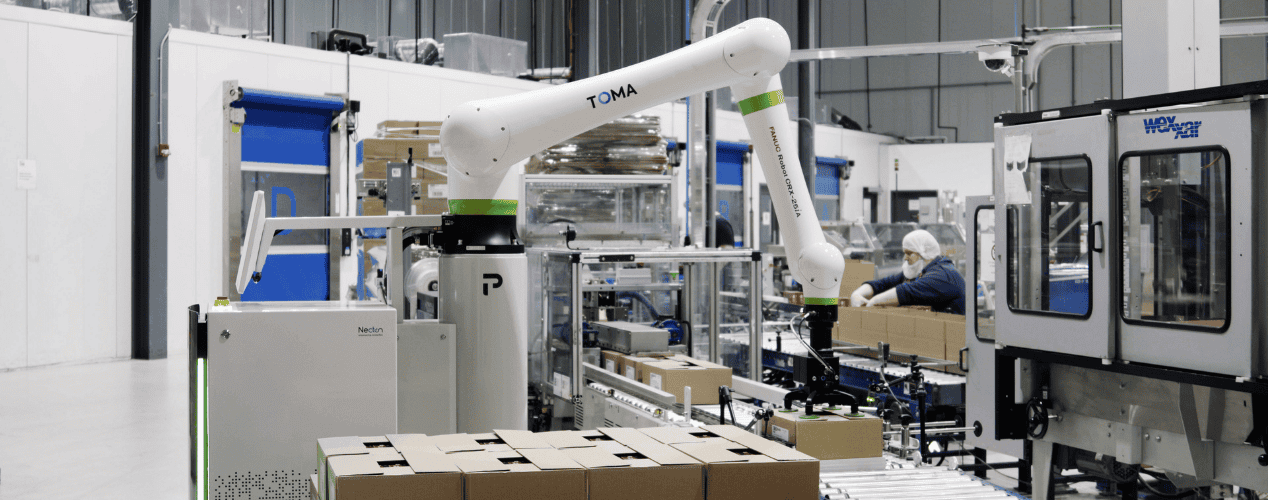

For example, the TOMA™ Palletizer, shown below, is designed for fast installation and easy configuration to accommodate a wide range of products, delivering true plug-and-play performance.

Speed of deployment is a competitive advantage. In many cases, pre-engineered modular palletizing solutions can be installed up to 50% faster than custom-built alternatives. However, speed can't come at the expense of performance.

That's why buyers are increasingly seeking transparency around system capabilities—including payload, cycle times, and scalability—right from the proposal stage. In 2026, clear, quantifiable proof of plug-and-play value will set the best solutions apart.

3. Rapid upskilling: palletizing systems accessible to all team members in 2026

As we look ahead to 2026, rapid upskilling will remain a top priority, making it critical for manufacturers to adopt palletizing systems accessible to all team members, regardless of background or experience.

Today's leading palletizing systems stand out by providing:

-

Simplified user interfaces with guided, step-by-step workflows

-

Built-in support for setup and pattern changes

-

Minimal training time, often measured in hours instead of weeks

This shift is driven by a simple reality: every moment lost in training slows down production. Teams must be able to onboard new staff swiftly, without relying on external experts or lengthy manuals. When an experienced operator leaves, their replacement should reach full effectiveness with minimal disruption.

According to Manufacturing Today, nearly 25% of the current U.S. manufacturing workforce is aged 55 or older, and up to 2.1 million jobs could remain unfilled by the end of the decade. That's why, more than ever, simplifying automation and accelerating upskilling are essential for ensuring operational resilience and future-readiness.

4. Self-service configuration becomes the industry standard in 2026

As we head into 2026, one trend is clear: self-service configuration has moved from a nice-to-have to an industry standard for palletizing systems.

With accelerated product changeovers and increasing SKU variability, manufacturers are demanding solutions that allow their in-house teams to adjust pallet patterns and product settings quickly, without relying on external integrators or specialists.

What does this mean for 2026-ready systems?

The leaders in the field now offer:

-

Guided recipe builders

-

Visual stack pattern tools

-

Intuitive drag-and-drop configuration interfaces

Modern HMIs make it possible for operators to enter box dimensions and auto-generate optimal stacking patterns. This empowers floor teams to handle product changeovers swiftly, minimizing downtime and removing the dependency on engineering or integrators.

Instead of writing code or scheduling a service call, operators can now make real-time changes directly through user-friendly interfaces—a must in sectors like food & beverage or logistics, where flexibility is essential.

Self-service configurability doesn't just save time—it enhances agility. By giving frontline team members the tools to build and edit recipes autonomously, manufacturers become more responsive to changing customer requirements and market dynamics. This shift is fully in line with broader industrial automation trends towards greater decentralization and workforce empowerment for 2026 and beyond.

Want a concrete example?

Watch Premier Tech's TOMA™ Palletizer demo to see how users can build and edit palletizing patterns in just a few taps—coding-free and operator-friendly.

5. Real-time data and seamless line integration define 2026 requirements

As we look to 2026, real-time data connectivity and seamless integration have become core requirements for palletizing systems.

Modern palletizers are no longer standalone units—end users now expect them to integrate directly with MES (Manufacturing Execution Systems), WMS, and other factory automation platforms to enable real-time visibility and effortless coordination across the production floor.

This integration brings several clear advantages:

-

Live performance monitoring: Operators can instantly track palletizer cycle times, fault history, and system uptime

-

Data-driven decision making: Real-time analytics enable teams to monitor overall equipment effectiveness (OEE), identify bottlenecks, and optimize production

-

Seamless system communication: Direct links with adjacent equipment—like conveyors, wrappers, and AGVs—reduce manual intervention and keep workflows running smoothly

Leading palletizing solutions for 2026 support industrial communication standards such as Ethernet/IP, OPC UA, and MQTT. This plug-and-play compatibility ensures they can connect easily to smart factory networks, without the need for custom engineering or complex IT projects.

For example:

A palletizer linked to an MES can automatically adjust stacking patterns in response to upstream product changes. It can also pause operations or send alerts if a downstream wrapper goes offline, keeping the whole packaging line synchronized.

With Industry 4.0 adoption accelerating and Industry 5.0 on the horizon, this level of integration is no longer optional. Manufacturers now demand plant-wide visibility, traceability, and flexibility from their automation investments—right from day one in 2026.

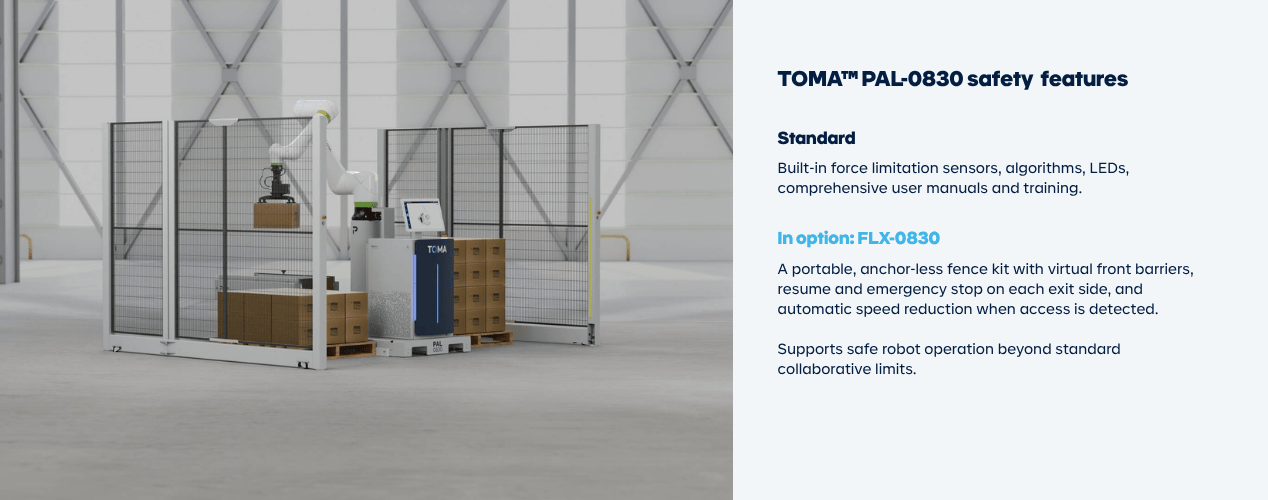

6. Safety shifts to application-based responsibility in 2026

With ISO 10218:2025 coming into force, 2026 will see a significant shift in how safety is addressed for robotic palletizing systems. The new standard shifts the focus from product-level compliance to how safety is ensured in each system’s actual operating environment.

Parts one and two of the updated standard introduce more specific criteria for functional safety and explicitly integrate collaborative robot requirements—elements previously covered by ISO/TS 15066.

As a result, manufacturers are now looking for palletizing solutions that deliver:

-

Clear, detailed documentation to support plant-specific risk assessments

-

Pre-configured safety zone templates tailored to various application layouts

-

Robust support for audits performed by integrators or third-party experts

These practical tools help clients more easily fulfill their legal safety obligations, especially as the responsibility for workplace safety increasingly rests with the system user. The industry trend for 2026 is a move away from relying solely on built-in safety features, and toward verifying safety as it is applied—within the unique context of each facility.

7. The line blurs between cobots and industrial robots in 2026

As we move into 2026, the traditional divide between collaborative robots (cobots) and industrial robots is rapidly disappearing.

Historically, manufacturers faced a clear choice: cobots were valued for their safety and ease of programming—but limited to lighter payloads and slower speeds. Industrial robots, on the other hand, delivered higher throughput and heavier lifting, but often required complex commissioning and substantial physical guarding.

In 2026, this distinction is growing less relevant as modern technologies converge:

-

Cobots can now handle payloads up to 30 kg, while offering extended reach for higher stacking and more demanding applications

-

Industrial robots incorporate cobot-like features, including intuitive user interfaces, integrated safety systems, and hand-guided teaching modes

-

Hybrid systems are emerging, operating at full speed when no humans are present and automatically reducing speed or entering safe collaborative modes when operators approach

This evolution gives manufacturers greater flexibility to select the optimal palletizing solution based on real operational needs, not arbitrary product categories. The conversation in 2026 is no longer simply “cobot or robot”—it’s about the right tool for each specific application, balancing speed, safety, payload, and ease of use.

What to expect from palletizing technology in 2026

Palletizing systems heading into 2026 are defined by user-friendliness, rapid deployment, and advanced connectivity. Manufacturers are raising the bar—expecting solutions that team members can operate, configure, and adapt without needing specialist expertise. Plug-and-play installation, real-time data integration, and robust built-in safety are now baseline requirements.

These trends mark a shift toward systems that:

-

Adapt quickly to changing needs

-

Minimize downtime

-

Fit seamlessly into existing production environments with minimal effort

As teams plan their next investments, choosing a palletizer that delivers flexibility, transparency, and long-term value from day one is critical for staying competitive in 2026 and beyond.

At Premier Tech, the TOMA™ PAL-0830 is engineered to help your operations meet—not just follow—the key trends shaping palletizing in 2026. With its user-friendly interface, rapid deployment, and advanced connectivity, the TOMA™ Palletizer is purpose-built to empower your team to move faster, work smarter, and stay ahead of industry demands.

If you’re planning your next investment in palletizing automation, discover how TOMA™ can future-proof your operations and keep you ready for everything 2026 brings.

Ready to see if TOMA™ is the right fit for your operations?

Start by answering a few quick questions to get your custom assessment: